Our Services

We perform mathematical modelling of membrane processes and membrane reactors

Membranes?

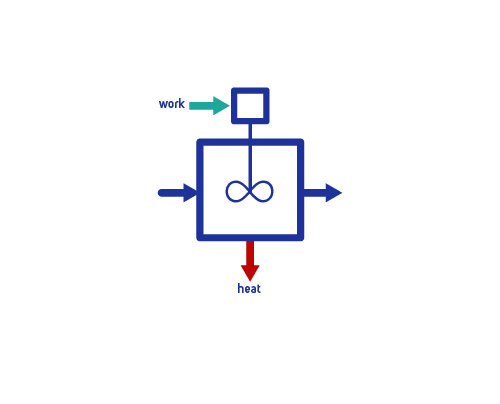

The membrane is a barrier at the interface between two adjacent phases. It is typically thin compared to the system dimensions and it controls the exchange of mass between the phases.

We deal with selective membranes, meaning that at least one component permeates through the membrane preferably to the others. In a membrane process, one phase is a mixture which is depleted in the component that is transferred to the other side of the membrane, while the other phase is enriched.

The permeation is caused by one or more driving forces, due to a gradient in chemical or electrical potential. If selective membranes are inserted in a chemical reactor, the integrated multi-functional device is called membrane reactor.

Modelling?

Modelling means creating a model that gives a simplified representation of a complex system.

The model can be used to study main features of the system, such as its response to specific inputs and its behaviour in specific operating conditions.

There are many types of models. We mainly work with mathematical models: a set of mathematical equations whose solutions describe the behaviour of the system and the values of its parameters.

The mathematical equations are based on physical principles, and they involve different analytical and numerical methods for their resolution. The mathematical models can be used as a handy tool able to quantitatively predict the system behaviour.

Membrane processes and membrane reactors can lead to a substantial process intensification: a cleaner, safer, smaller and more efficient alternative to perform an existing process

Membranes & Membrane Reactors Modelling

Membrane Modules

Membrane reactor models can be integrated in larger models for membrane modules. Whether it is operated in flow – or batch – or semi-batch process, we can describe the module for different configurations:

Flat-sheet

Tubular

Hollow fiber

Permeation Models

Permeation or transport models describe the flow of chemical components through the membrane for different membrane types (porous, microporous, dense), materials (polymeric, ceramic, carbon, metallic) and processes:

Micro/Ultra/Nano – Filtration

Reverse osmosis

Pervaporation

Gas separation

Membrane distillation

Membrane Reactors

We can perform calculations to support reactor design stage and optimization. Our models can deal with different chemical reactions and reactor configurations:

Packed bed

Fluidized bed

Our Customized Services

Customized Models

Development

We can invastigate new applications, developing customized models for innovative solutions of your interest

Consultancy on

Membrane Processes

We provide consultancy to verify if membrane technology can be sucessfully applied to your specific process

Process Design & Upscaling

Techno-Economic Analysis

Optimization of the system through detailed sensitivity analysis on operation parameters of the system. Definition of performance indicators and estimation of investments, operating costs, production costs and revenues.

Material & Energy Balances

We can perform material balance of the system to determine the correct size of the plant components. We also perform energy balances to maximize energy efficiency and minimize entropy generation.

Sustainability Analysis

We do what we can to reduce costs and greenhouse gases emissions thanks to an improvement in process efficiency. Sustainability Analysis allows to assess the overall emissions of the technology.

Interested by our services? Can we help you?